What Is the SCADA Control System and Why It’s Critical for Modern Manufacturing

Learn what SCADA systems are, how SCADA control systems work, and why they’re essential for smart manufacturing and automation success.

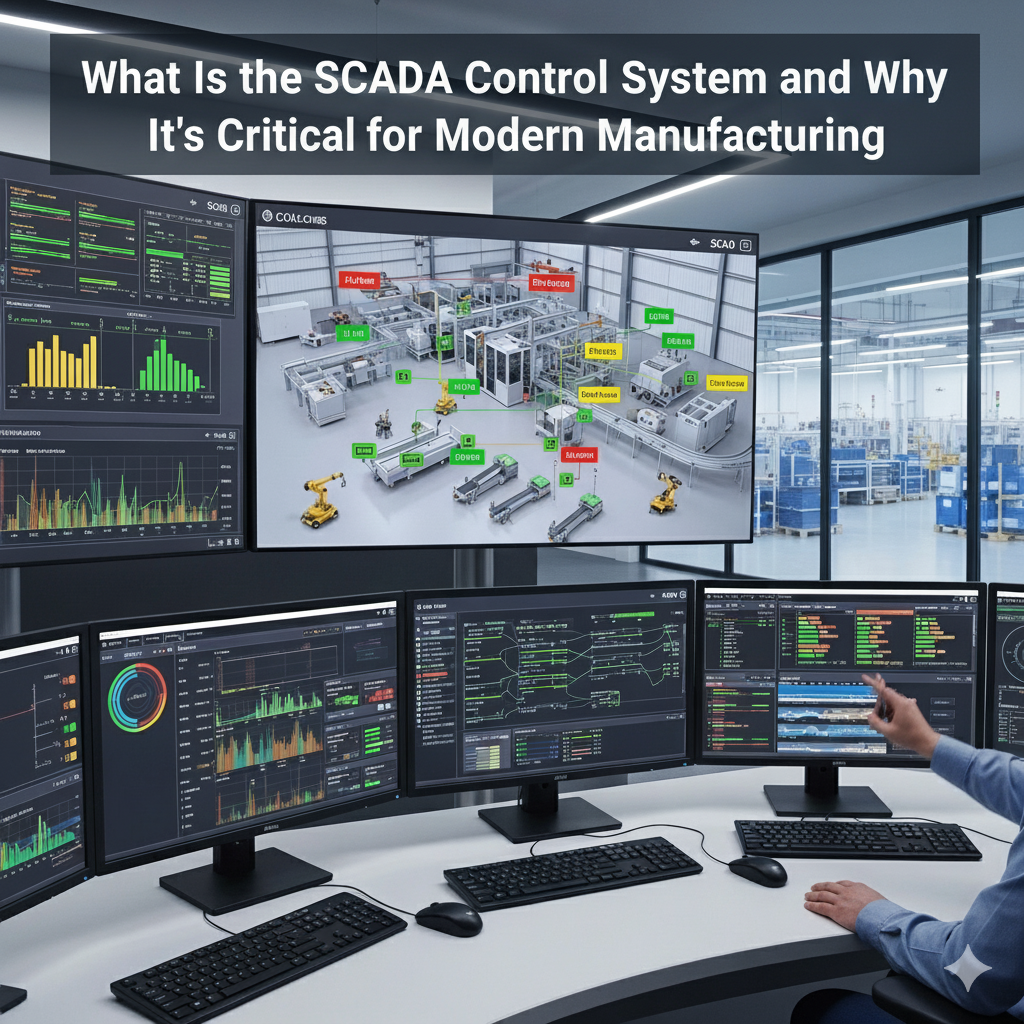

Supervisory Control and Data Acquisition (SCADA) has become the backbone of modern manufacturing. From monitoring production lines to enabling predictive maintenance, SCADA control systems empower factories to operate with efficiency, precision, and safety.

But what exactly is SCADA, and why is it so important today?

What Is SCADA?

At its core, SCADA (Supervisory Control and Data Acquisition) is a software-and-hardware system designed to collect, process, and display real-time data from manufacturing equipment, sensors, and devices.

SCADA Components:

– Sensors/RTUs (Remote Terminal Units): Capture real-time data from machines.

– PLCs (Programmable Logic Controllers): Execute automation logic.

– Communication Networks: Transfer data between devices.

– SCADA Software: Central dashboard for operators to monitor and control processes.

How SCADA Control Systems Work

A SCADA system bridges the factory floor (OT) with enterprise decision-making (IT). Here’s how:

1. Data Acquisition: Sensors and PLCs collect temperature, pressure, speed, and other critical metrics.

2. Data Transmission: Information is sent securely to a centralized SCADA software platform.

3. Data Processing: The SCADA software analyzes data, triggering alerts or automated responses.

4. Operator Interface: Plant managers can remotely monitor, visualize, and control operations.

Why SCADA Is Critical for Modern Manufacturing

– Enhanced Visibility: Real-time data dashboards enable proactive decision-making.

– Improved Efficiency: Automation reduces downtime and production bottlenecks.

– Predictive Maintenance: SCADA data analytics prevent costly equipment failures.

– Regulatory Compliance: Detailed reporting ensures FDA, ISO, or OSHA standards are met.

– Scalability: SCADA systems evolve with Industry 4.0, integrating AI and MES.

Real-World Applications of SCADA in Manufacturing

– Food & Beverage: Monitor temperature and humidity for quality compliance.

– Pharmaceuticals: Ensure traceability and batch consistency.

– Automotive: Track robotic assembly line efficiency.

– Energy & Utilities: Manage distributed assets like turbines and substations.

The Future of SCADA: AI and Digital Twins

AI-enhanced SCADA systems are ushering in the next era of manufacturing. With predictive analytics, anomaly detection, and digital twin simulations, SCADA automation is becoming a cornerstone of smart factories.