SCADA Software Integration

We offer the most comprehensive solutions for your data collection, automation, and HMI needs using Inductive Automation’s Ignition, Rockwell Automation’s FactoryTalk, Siemens’ Tia Portal and/or Automation Direct.

We offer the most comprehensive solutions for your data collection, automation, and HMI needs using Inductive Automation’s Ignition, Rockwell Automation’s FactoryTalk, Siemens’ Tia Portal and/or Automation Direct.

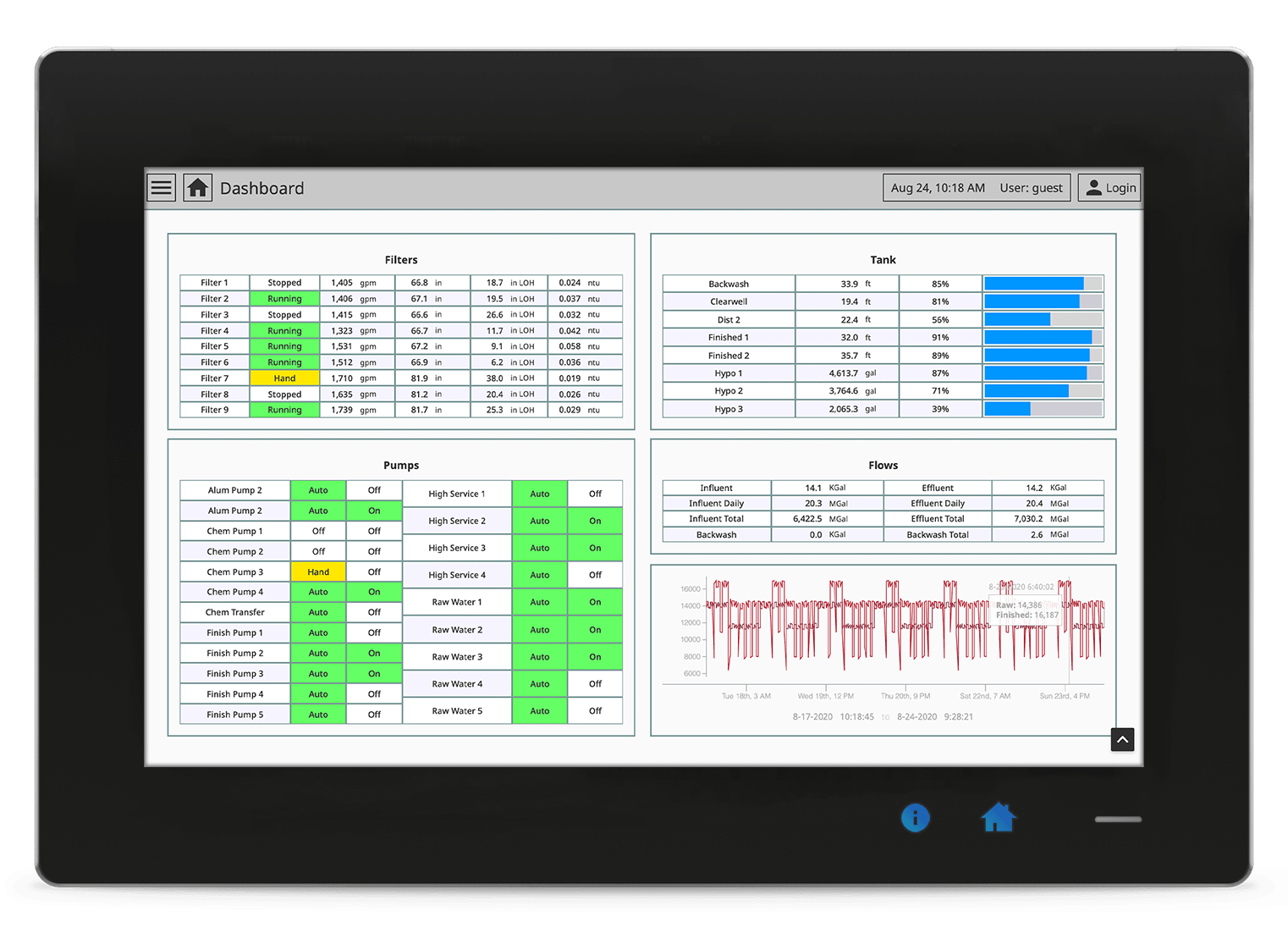

HMI serves as the local connection between man and machinery. This function can be as simple as on screen run buttons or an entire workflow management tool that allows operators to transform the pen and paper order tasks to a database powered keypad input.

SCADA describes the system of systems that connects device controllers, instruments, reporting, recipes, and HMIs which are providing automation in your facility. This can be anything from historical data collection of process control tags to a larger application which serves management and operators in nearly every aspect of process and order documentation.

The Impact of SCADA Systems and Ignition in Modern Manufacturing

The evolution of manufacturing practices has been marked by transformative innovations that enhance efficiency, quality, and responsiveness to market demands. From Henry Ford’s pioneering assembly line to the lean principles of the Toyota Production System, each era has introduced methodologies that shape industrial operations. In today’s context, the integration of SCADA (Supervisory Control and Data Acquisition) systems, particularly through platforms like Ignition by Inductive Automation, represents a significant advancement driving Industry 4.0 capabilities.

SCADA’s Role in Enhancing Manufacturing Efficiency

Manufacturing operations have benefited tremendously from SCADA systems, which provide real-time monitoring, control, and data acquisition capabilities. These systems enable seamless integration of diverse industrial processes, enhancing operational efficiency and reducing downtime.

Benefits of Using Ignition SCADA

SCADA Integration in Industry 4.0

Industry 4.0 represents a paradigm shift towards smart manufacturing, characterized by interconnected systems, autonomous processes, and data-driven decision-making. SCADA systems play a pivotal role in this transformation by:

Case Study: Distribution Centers

Modern distribution centers exemplify SCADA’s impact on logistics and manufacturing efficiency. Facilities like those operated by Wal-Mart rely on SCADA for:

Case Study: Inspection Technologies in Superconductor Wire Production

In superconductor wire production, advanced inspection technologies, including precise monitoring of dimensions and material conditions, coupled with temperature monitoring systems, are pivotal in enhancing quality control processes.

In conclusion, SCADA systems such as Ignition are instrumental in modern manufacturing’s pursuit of efficiency, quality, and agility. By integrating advanced automation, real-time data analytics, and scalable solutions, Ignition enables manufacturers to thrive in Industry 4.0 environments. As manufacturing continues to evolve, SCADA’s role in enhancing operational visibility, optimizing resource utilization, and driving innovation remains indispensable. Embracing SCADA solutions like Ignition positions manufacturers to achieve sustainable growth, competitive advantage, and operational excellence in a digitalized global economy.