We provide advanced solutions tailored to your data collection, automation, and HMI needs, utilizing leading platforms such as Inductive Automation’s Ignition, Rockwell Automation’s FactoryTalk, Siemens’ TIA Portal, and Automation Direct.

Human Machine Interface (HMI)

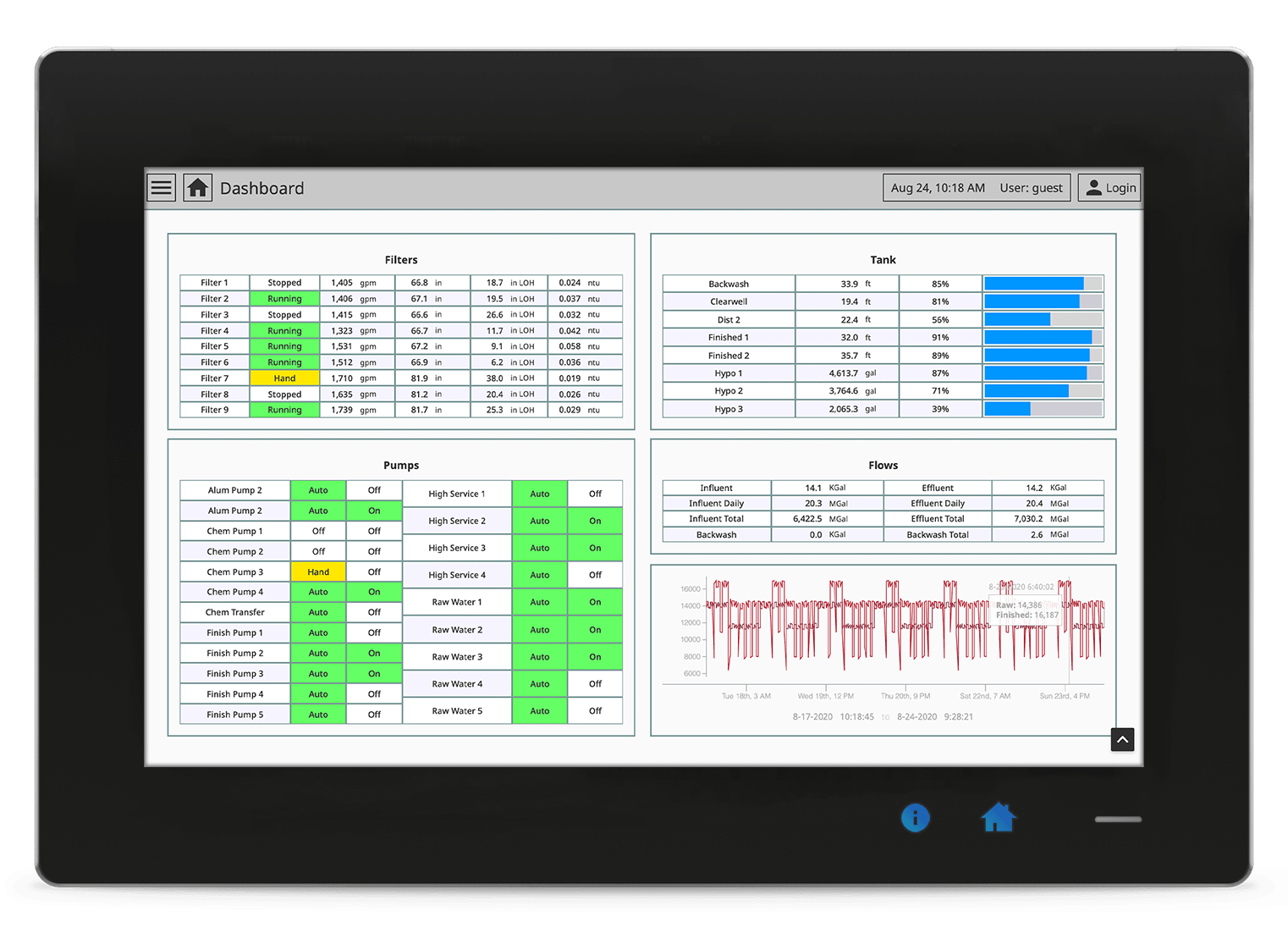

HMI acts as the interface between operators and machinery. It ranges from simple on-screen controls to sophisticated workflow management tools that transition manual processes to efficient, database-driven inputs.

Supervisory Control and Data Acquisition (SCADA)

SCADA integrates device controllers, instruments, reporting systems, recipes, and HMIs, enabling comprehensive automation within your facility. It encompasses everything from historical data collection and process control to extensive applications supporting management and operational documentation.

Technical Capabilities

• Barcode reading

• Mobile, Responsive, Web-based Deployment

• Unlimited Tags, Clients, Connections

• SQL Databases

• Cross-Platform

• Role Based Security

• Data Logging

• High Speed Control

• Display Images, Slideshows, Drawings, and other files

• Customized Navigation

• Alarm Notification

• Preventative Maintenance

• Quality Management

• User Management

• Production Report Management

• Connect Instruments for IoT

• Maps

• Legacy Devices

The Impact of SCADA Systems and Ignition in Modern Manufacturing

SCADA (Supervisory Control and Data Acquisition) systems, particularly Ignition by Inductive Automation, are driving Industry 4.0 capabilities by providing real-time monitoring, control, and data acquisition across manufacturing operations.

Key Benefits of Ignition SCADA:

- Unified Platform: Simplifies connectivity across diverse industrial protocols and equipment without complex licensing

- Web-Based Access: Perspective module enables remote monitoring and control from any browser-enabled device

- Scalability: Modular architecture supports applications from small-scale to enterprise-level deployments

- Advanced Analytics: Real-time and historical data analysis optimize processes and predict maintenance needs

SCADA’s Role in Industry 4.0:

SCADA systems enable interoperability between equipment, process real-time operational data, and automate workflows—reducing costs, minimizing waste, and improving quality. They facilitate predictive maintenance, quality assurance, and adaptive production strategies essential for competitive manufacturing.

Real-World Applications:

- Distribution Centers: Monitor conveyor systems, optimize throughput, and provide real-time alerts to prevent downtime

- Superconductor Wire Production: Control inspection technologies (eddy current, laser micrometers), monitor temperatures, track billet traceability via barcodes, automate label printing, and manage wire type recipes for consistent quality

SCADA systems are indispensable for achieving operational excellence, enhancing visibility, and driving innovation in modern digitalized manufacturing environments.